Importance of Pallet Racks in the Heavy Duty Manufacturing Industry

It is important that the heavy duty manufacturing industries that handle products like tires, vehicles, and material handling equipment, among others, need an organized way of managing their inventories. This is essential to assure quick and safe retrieval of raw materials, semi or finished goods. If these items are not stored properly, there are higher chances of goods damage, incurring a huge loss to those who are involved. Moreover, improper stacking also consumes lots of space, causing difficulties to accommodate large quantities of products safely at a time. How can you overcome this storage problem in the heavy-duty manufacturing industry?

There is an innovative, yet cost-effective storage solution known as heavy duty pallet racks that help streamline your inventory in the most organized manner. Let us know more about this efficacious material handling and storage solution in this post.

There is an innovative, yet cost-effective storage solution known as heavy duty pallet racks that help streamline your inventory in the most organized manner. Let us know more about this efficacious material handling and storage solution in this post.

Get the Most Out of your Warehouse Space

Heavy duty pallet racks assure easy inventory management. How they make it? The following points let you know the reasons.

-

As mentioned earlier in the post, pallet tracks consume less floor space as they are custom designed with several racks one above the other.

-

The metal pallet racking system allows quick and easy retrieval of goods. This contributes to augment the employees -productivity and efficiency.

-

With more vertical space, heavy duty pallet racking system helps store thousands of items safely and securely, where heavy stock capacity is needed.

-

These heavy duty pallet racks ensure utmost safety for all working in their vicinity. They are robustly built using the finest grades of materials and their sturdiness helps prevent accidental collapse. In short, these racks help minimize injuries and mishaps.

-

They are manufactured to withstand the rigors of the everyday loading and unloading using forklifts from both ends and on either side. They are impact resistant and are resistant to rust, other contaminants and wear-and-tear.

-

When designed to easily handle multiple items, they can be modified as per the specifications of the products being stacked.

-

They are easy-to-install and dismantle for further use, thus assuring that your entire inventory moving efficiently

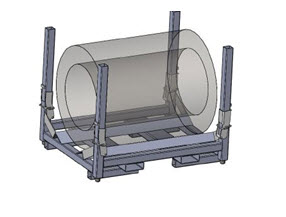

Considering the rising demands for pallet racking systems, they are designed and manufactured in numerous ways. Rather than the standard designs available, manufacturers provide the option of customizing the racks to best suits the application requirements. A few of the common types of heavy duty pallet racking systems include metal pallets, cradle platters, tab stack pallets, fat deck pallets, among others. Since the proper rack system is critical to your business profitability, it is important that they should be wisely selected from the several models available. The right rack system must be selected by evaluating the following;

- How much space is available in the application area?

- How much/many products are to be stored?

- How much is the goods weight?

- What are the ways employed for product loading and retrieval?

- How often are the products accessed?

- What are the conditions exist in the application areas?

Last but not the least, it is extremely important that you procure the racking solution from leading pallet rack manufacturers in order to assure optimum quality, and thus to achieve the expected results. Only the prominent pallet rack manufacturers offer you varied options to choose from, whilst also providing an option for customizing. One such trusted names in the industry who is known for extensive manufacturing engineering experience is SPS Ideal Solutions. Given any heavy duty pallet racks requirement, they guarantee to provide you with the industry-best at the best deals on time.

Related Posts:

- 6 Most Important Things to Consider Before Buying Pallet Racks.

- How to Select the Best Metal Pallet Racks for Your Facility

- How to Find the Right Size of Pallet Rack?

- A Comprehensive Guide on Pallet Rack Flue Spaces

About The Author