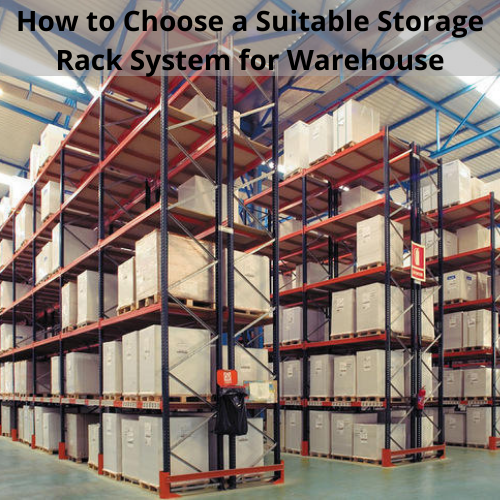

How to Choose a Suitable Storage Rack System for Your Warehouse?

Storage rack systems are an important investment for any business with a warehouse or storage area. The right racks can make all the difference in terms of efficiency and safety, holding more product in less space and preventing accidents. Warehouse storage rack systems are used in a number of industries, including automotive, retail, and grocery. There are many different types of storage racks available, each with its own advantages and disadvantages. It is important to select the right type of rack for your warehouse to ensure that products are stored properly. This post lists a few factors to consider before choosing a warehouse pallet rack for your facility.

Tips to Choose the Right Warehouse Rack for Your Storage Facility

When selecting warehouse racks, there are a few factors to consider including the weight of the items to be stored, the dimensions of the items, and the height of the warehouse. The height of the ceilings and the width of the aisles also need to be taken into account. In addition, it is important to select warehouse storage rack systems that are compatible with the existing material handling equipment in order to minimize worker injuries and maximize efficiency. The other major factors to consider include:

- Warehouse Design and Environment: The warehouse rack and storage system you choose will have a significant impact on the productivity of your warehouse workers and on the efficiency of your warehouse operations. You must take into account the design of your warehouse and the environment in which it operates before making a decision about what type of racks to install. When it comes to the design of your warehouse, there are a few things you need to take into consideration before choosing your storage racks. The layout of your warehouse, the elevation of your warehouse, and the climate of your warehouse can all have an impact on what type of storage racks will be best for you. For example, if your warehouse with high ceiling, you will need taller storage racks in order to make use of the space. In a hot, humid environment, for example, you will need racks that allow for good air circulation to prevent the products from becoming damaged by moisture. In a cold environment, you will need racks that can withstand the cold and that will protect the products from frost damage.

- Type of Products to be Stored: There are many types of warehouse pallet racks available in the market, and the type and shape of the products to be stored should be considered before choosing the racks. Some types of racks are designed to store pallets, while others are designed to store boxed items or individual items. The shape of the products to be stored is also important, as some racks are designed for square or rectangular products, while others are designed for products that are cylindrical or irregular in shape.

- Forklift Accessibility: When it comes to warehouse storage racks, forklift accessibility should be one of your top considerations. If the racks you choose are not accessible to forklifts, your employees will have to move inventory around manually, which can be a time-consuming and difficult process. Warehouse racks that are too high or too low can make it difficult for forklifts to reach the inventory, which can lead to wastage of time and frustration for employees. There are a few things you can do to make sure your racks are accessible to forklifts. First, make sure the racks you select have open spaces between the shelves. This will allow the forklifts to get in close and move the inventory around easily.

- Width of Aisles: It is also important to consider the width of the aisles between the racks. If the aisles are too narrow, the racks will take up more space than necessary and could block traffic. If the aisles are too wide, the racks will be less efficient in terms of storage space.

Needless to say, the type of storage racks used can have a major impact on the warehouse as a whole. If the wrong racks are chosen, it can lead to wasted space, time, and money. The wrong type of racks can lead to all sorts of organizational and storage issues. There are many different types of storage racks available on the market. It is important to choose the right type for the specific warehouse.

When it comes to finding the right storage racks for warehouses, it is important to connect with leading manufacturers like SPS Ideal Solutions. By working with such a reputable manufacturer, you will have access to high-quality products that meet your specific needs. In addition, you will be able to benefit from the manufacturer’s years of experience and expertise in the field. Take the time to research different manufacturers and compare their products and services. This will help you find the right one for your business.

Related Posts:

- Top 5 Essential Tips to Minimize Warehousing Cost

- 7 Important Warehouse Pallet Racking Tips to Maximize Productivity

- What Essential Factors One Must Consider Before Warehouse Pallet Rack Installation?

- Optimize the Warehouse Space and Efficiency Using the Right Pallet Racks

About The Author