Tips to Speed up Wind Turbine Assembly Process

Wind energy is becoming increasingly important as a source of renewable energy, providing a clean & sustainable alternative to fossil fuels. Wind turbines generate electricity by harnessing the power of wind, and are becoming more and more popular as the world shifts towards cleaner & more sustainable energy sources. Wind turbine demand is growing rapidly around the world as countries set ambitious targets for reducing greenhouse gas emissions & switching to renewable energy sources. Wind turbines can be installed on land or offshore, and can range in size from small turbines for residential use to large commercial turbines that can power entire cities.

The significance of wind energy as a renewable resource is rapidly escalating, offering an eco-friendly solution to the global reliance on fossil fuels. Wind turbines, which convert wind energy into electricity, are at the forefront of this transition towards more sustainable energy practices. The demand for wind turbines is surging globally as nations ambitiously aim to cut greenhouse gas emissions and pivot to renewable sources of energy. These turbines, which can be placed both onshore and offshore, vary in size from smaller units suitable for individual homes to massive turbines capable of powering entire municipalities.

With the rising interest in wind turbines comes the challenge of streamlining their assembly processes to keep pace with demand. Constructing wind turbines is a detailed and labor-intensive operation, involving various components that must be deftly assembled and installed. Enhancing the efficiency of these assembly lines is crucial for manufacturers to scale up production and cater to the increasing appetite for renewable energy while also reducing the production footprint by conserving energy and raw materials.

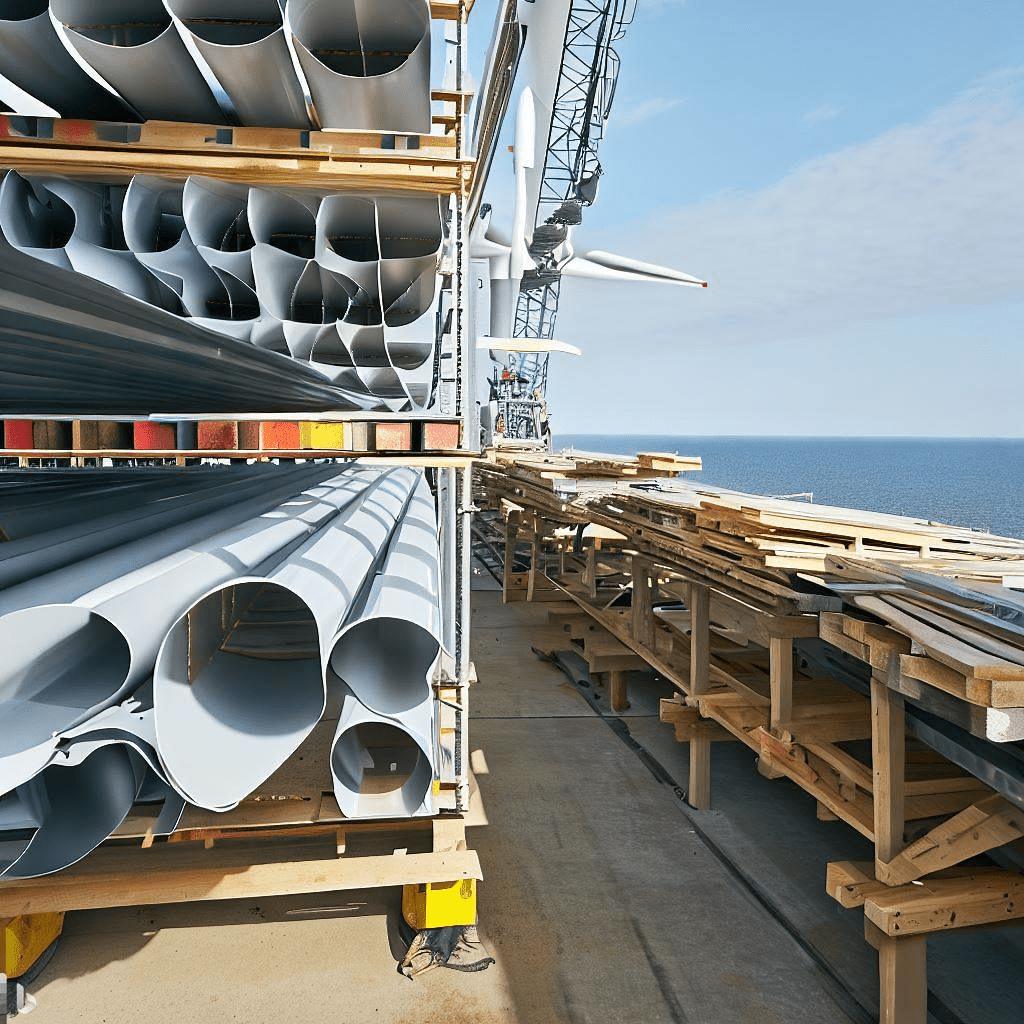

Transporting and Storing of Components

The logistics of transporting and storing wind turbine parts are integral to the assembly process. This includes:

Trucks and Trailers: Specialized flatbed trucks and trailers are employed to haul components from manufacturing sites to assembly locations. These vehicles are equipped to manage large and hefty items through features like hydraulic lifts and secure tie-downs.

Shipping Containers: For international or long-distance transportation, shipping containers offer a robust option, protecting parts during transit.

Warehousing: Given the considerable size and weight of turbine parts, warehouses with features like overhead cranes and controlled environments are utilized.

Racks: To maintain organization and safety, racks play a pivotal role in keeping and moving components efficiently within the manufacturing and assembly zones. Industrial racks are used prevent damage and help to ensure that wind turbines are assembled quickly & correctly.

Laydown Yards: Laydown yards serve as external storage spaces for items too bulky or heavy for indoor storage.

Speed up Wind Turbine Assembly Process

Improving the assembly time for wind turbines involves several strategies, such as:

Optimize Planning and Coordination: Utilizing project management tools aids in devising detailed schedules and fosters clear communication, thereby reducing slowdowns.

Streamline Logistics and Material Handling: By optimizing warehouse layouts and adopting robotics, the movement of parts can become more efficient, expediting the assembly process.

Optimize Assembly Process: Adopting modular designs and using standardized parts can simplify construction, decreasing the variety of tools needed.

Enhance Safety Measures: Providing comprehensive training and ensuring the use of protective gear help uphold safety standards, preventing accidents and delays.

Use Technology: Employing virtual and augmented reality for training and assembly simulations, alongside sensors for monitoring turbine performance, can pre-emptively address maintenance issues.

Importance of Optimizing Wind Turbine Assembly

Increased Production Capacity: Streamlining assembly procedures allows manufacturers to produce more turbines in less time, meeting the rising demand for renewable energy sources.

Cost Reduction: Time-consuming wind turbine assembly processes incur higher labor and resource costs. Optimizing assembly minimizes these expenses, enhancing the competitiveness of wind energy against fossil fuels.

Environmental Impact: Efficient assembly reduces energy and resource consumption during manufacturing, lowering the carbon footprint of wind turbine production.

Reliability and Performance: Precise wind turbine assembly ensures components are correctly installed, decreasing the likelihood of malfunctions or breakdowns and enhancing turbine performance and longevity.

Safety: Proper training and safety measures for workers reduce the risk of workplace accidents and injuries during assembly operations.

What is Wind Turbine Fabrication?

Wind turbine fabrication is the process of creating the components that comprise a wind turbine. This includes the manufacture of rotor blades, towers, nacelles (which house the turbine’s generator and other internal components), hubs, gearboxes, and other associated equipment. Fabrication includes a variety of techniques such as cutting, sculpting, molding, welding, machining, and assembling these components to exact specifications.

Wind turbine fabrication is an important part of the renewable energy sector because the reliability and performance of the components produced have a direct impact on the overall efficiency and longevity of wind turbines in harvesting wind energy. Efficient and precise fabrication procedures are critical for addressing the growing global demand for wind turbines and accelerating the transition to a sustainable energy future.

How Turbine Fabrication Helps in Optimizing Wind Turbine Assembly Process

Efficient wind turbine fabrication considerably improves the assembly process in various ways:

Quality Assurance: Turbine fabrication procedures follow stringent quality standards, guaranteeing that components are made to exact specifications. High-quality components reduce the need for modifications or corrections during assembly, which streamlines the entire process.

Customization and Standardization: Fabrication techniques allow for customization of turbine components to suit specific project requirements while also promoting standardization where feasible. Customization ensures that turbines are tailored to varying environmental conditions, while standardization simplifies assembly by reducing the complexity of component integration.

Material Innovation: Advances in fabrication technology enable the use of advanced materials that enhance the performance and durability of turbine components. Lightweight yet robust materials for rotor blades and towers, for example, improve turbine efficiency and longevity. These materials also facilitate easier handling and installation during assembly.

Cost Reduction: Efficient fabrication processes help drive down production costs by optimizing manufacturing techniques, minimizing waste, and maximizing resource utilization. Cost-effective fabrication translates to lower overall turbine manufacturing costs, making wind energy more economically viable.

Streamlined Supply Chain: Effective coordination between fabrication facilities and assembly sites ensures timely delivery of components, reducing delays in the assembly process. Well-managed supply chains optimize logistics, minimizing transportation costs and lead times.

Innovative Technologies: Fabrication processes leverage innovative technologies such as automation, robotics, and additive manufacturing to increase efficiency and productivity. These technologies enable faster production cycles, reduce manual labor requirements, and improve the precision of component manufacturing.

We encourage wind turbine manufacturers & contractors to consider these tips when developing their assembly processes. By doing so, they can help to make wind energy more accessible and affordable, which will also contribute to the global effort to reduce greenhouse gas emissions & combat climate change.

Frequently Asked Questions

What are some challenges in wind turbine fabrication?

The challenges of wind turbine fabrication include refining manufacturing processes to decrease costs, guaranteeing supply chain resilience, enhancing component efficiency and dependability, and managing transportation and logistical concerns.

What are some challenges faced during wind generator assembly?

Wind generator assembly challenges may include adverse weather conditions, logistical complexities associated with transporting large components, coordinating assembly activities with other construction activities at wind farm sites, and maintaining quality control throughout the assembly process.

Can wind generator assembly be customized for specific project requirements?

Yes, wind generator assemblies can be tailored to fulfill individual project needs such as turbine size, tower height, and installation site environmental conditions. Customization may include changes to component design, assembly techniques, and system integration in order to improve performance and efficiency.

Related Posts:

- How to Simplify Assembly to Storage Workflow?

- How to Solve Most Common Warehouse Management Challenges

- 6 Amazing Benefits of Warehouse Storage Solutions

- How To Identify Areas Where Rack Guarding Is Needed?

About The Author