Sheet Metal Fabrication Process: Turning Raw Metal into Durable Storage Solutions

From industrial storage racks to custom material handling systems, every durable metal component starts with a precise sheet metal fabrication process. This manufacturing method transforms flat metal sheets into functional parts through cutting, bending, forming, and welding. Understanding different sheet metal fabrication processes is essential for businesses that rely on strength, accuracy, and customization in their products. At SPS Ideal Solutions, we use advanced techniques and CNC technology to deliver high-quality industrial storage solutions. In this guide, we’ll walk you through the complete sheet metal fabrication process, the steps involved and why it’s crucial for creating reliable, long-lasting storage systems.

What Is the Sheet Metal Fabrication Process?

Sheet metal fabrication is the method of converting flat metal sheets into functional parts or complete products. This is achieved through a series of steps that include cutting, forming, joining and finishing. The process is used in many industries, but for SPS Ideal Solutions, it’s the foundation of our industrial racks, pallets, and custom material handling systems.

By using CNC-controlled machines and advanced fabrication processes, we can produce parts with high precision, ensuring they fit perfectly into larger assemblies and last for years under heavy use.

Key Steps in the Sheet Metal Fabrication Process

- Design & Planning: Every project begins with a design, often created in CAD software. This stage ensures dimensions are accurate and the product meets functional requirements before fabrication begins.

- Material Selection: Choosing the right sheet metal such as stainless steel, aluminium, or mild steel affects the product’s strength, weight, and resistance to corrosion. Learn more about the importance of material selection in sheet metal fabrication here.

- Cutting: The raw sheet is cut into the required shape using methods like laser cutting, water jet cutting, or CNC punching. These processes ensure clean edges and precise dimensions.

- Forming & Bending: After cutting, sheets are bent or rolled into the required angles and curves. This step adds strength and gives the metal its intended shape for assembly.

- Welding & Assembly: Individual parts are joined using techniques like MIG or TIG welding to form a complete structure. Strong welds ensure durability and long-term performance.

- Surface Treatment: Finishing processes like powder coating, galvanizing, or phosphate films are applied to protect against corrosion and improve the product’s lifespan and appearance.

Common Sheet Metal Fabrication Processes

Several techniques are used to achieve the final result. At SPS Ideal Solutions, the most common include:

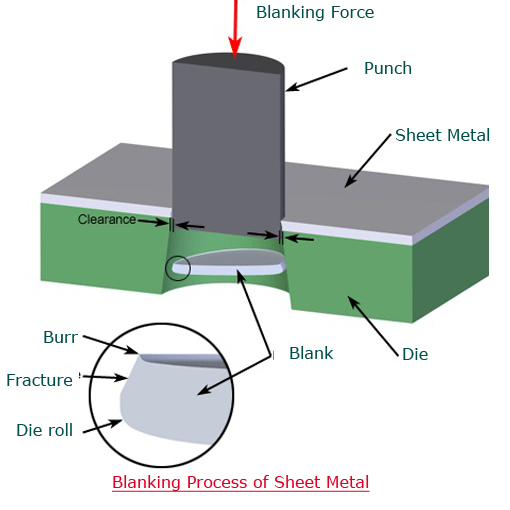

- Blanking: Punching a specific shape out of the sheet to create a workpiece.

- Bending: Creating angles and curves for added strength.

- Riveting: Joining parts using secure metal rivets.

- Cutting: Using lasers, water jets, or CNC for precise shapes.

- Forming: Shaping metal through rolling or stamping.

- Welding: Fusing parts into a single durable structure.

These processes allow us to create storage racks and pallets that meet strict industrial requirements.

Advantages of Sheet Metal Fabrication

Versatility: Sheet metal fabrication has significant adaptability, allowing producers to build a wide range of forms and sizes for a variety of purposes. Sheet metal can be customized to fit a variety of applications, including automotive, aerospace, construction, and electronics.

Strength and Durability: Sheet metal components are widely recognized for their strength and durability. Manufacturers may create durable parts that can survive heavy loads, high temperatures, and harsh environment conditions by using the proper materials and production procedures.

Cost-Effectiveness: Sheet metal fabrication processes are usually cost-effective, particularly in mass production. One of the most critical factors influencing this cost-effectiveness is efficient material utilization. Sheet metal fabrication employs precision cutting and forming techniques to minimize material waste while improving raw material productivity.

Customization: One of the primary advantages of sheet metal fabrication is its ability to be customized to exact design specifications. Sheet metal components can be made to the exact dimensions, shapes, and specifications needed for a specific application. This alteration ensures that components integrate seamlessly into the finished product, hence boosting performance and functionality.

Efficiency: With technical advancements and automation, sheet metal production processes have become more efficient. Computer-controlled machinery and robotics enable high-speed production, resulting in quicker turnaround times and shorter project lead times.

Design Flexibility: Sheet metal manufacturing offers remarkable design flexibility, allowing engineers and designers to try out new ideas and innovative solutions. Sheet metal may be shaped and manipulated to produce complex shapes, intricate patterns, and smooth transitions between components, allowing practically any design concept to be achieved.

Applications in Industrial Storage Solutions

SPS Ideal Solutions uses advanced sheet metal fabrication processes to produce:

- Industrial storage racks for warehouses and factories

- Durable pallets designed for safe material handling

- Custom metal containers tailored to specific operations

- Specialized material handling systems for heavy-duty use

Our Custom Metal Fabrications allow you to get products built to your exact requirements.

Quality and Precision at SPS Ideal Solutions

Quality control is integrated into every stage of our fabrication process. From material selection to final inspection, we ensure every component meets strict tolerances and industrial standards. This attention to detail results in products that perform reliably, even in demanding environments.

Conclusion

The sheet metal fabrication process is more than just cutting and welding; it’s a combination of design, precision, and expertise that turns raw metal into durable storage solutions. At SPS Ideal Solutions, we combine advanced CNC technology with years of experience to deliver racks, pallets, and custom metal fabrications that support your operations and stand the test of time.

FAQs About Sheet Metal Fabrication

- What is the sheet metal fabrication process?

It’s the method of turning flat metal sheets into functional products using cutting, bending, welding, and finishing techniques. - What materials are commonly used?

Stainless steel, aluminium, and mild steel are most common due to their strength and corrosion resistance. - Which cutting methods are best?

Laser and water jet cutting are preferred for precision, while CNC punching is great for repetitive shapes. - Why is surface treatment important?

It protects against corrosion, improves aesthetics, and extends the product’s life. - Can sheet metal fabrication be customized?

Yes, designs can be tailored for specific dimensions, load capacities, and industrial applications.

Related posts:

- Learn About the Importance of Material Selection in Sheet Metal Fabrication

- 9 Ways to Save Money on Metal Fabrication

- Everything You Need to Know About Custom Metal Fabrication

- Metal Fabrication Industry Trends

About The Author

What Is the Sheet Metal Fabrication Process?