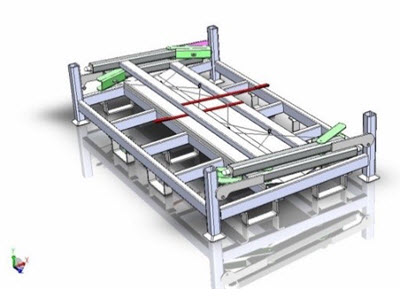

Film Roll Storage Folding Rack

We designed a film roll storage folding rack to replace a rigid floor mounted rack system at a major extrusion plant in the mid-west state of Indiana. The challenges and solutions are detailed in the below section.

Challenge

Our client was using a fixed rigid rack system for storing rolls of film. The following problems were identified:

- The rigid racking was creating a major bottleneck for the fork truck traffic

- The racks did not have adequate space to hold the production flow coming into storage

- If additional fixed rigid racking was installed, it would further complicate the fork truck traffic into the storage area

Solution

Our solution was to create a racking system that was dynamic in terms of storage volume. Additionally, the racks needed to ensure ease of fork truck entry. A folding rack that would allow for transfer of the rolls of bundling film onto a roll transport/storage roll rack was used. Once the roll was on the movable rack it could be fork trucked into the storage area.

- A folding design would provide space savings to accommodate the flexibility of production volumes adjusted to meet changes in end user demand

- The roll rack had to be easy to operate for the film extruder operators

- Safety was very top of the list – the client has had 4 years with no injuries

- The roll rack would be the first transportable steel roll rack at this plant.

- The roll racks would be stacked 3 high, although they can be safely stacked 4 high

Rack Design Features

The custom designed rack featured:

- Single cable release

- Each corner is vertically secure by a channel section that completely captures the open pivot of the hinged leg

- Hand strap assists in easy lowering of the side section onto the roll rack deck

- Cradle deck protects the film from becoming “blocked” in storage

- Funnel feet provide easy alignment for stacking

Collaborating with SPS Ideal Solutions has allowed our client to make use of cutting-edge technology for development of a product that is dynamic in nature. It offers immense benefits when in use, and can be stored without occupying much space when not in use. With development of a versatile rack, the client was able to solve all the problems they were facing when using traditional tacking systems.

About The Author