Custom Industrial Storage Containers for Automation & Robotics Components

At SPS Ideal Solutions, we design custom industrial storage containers optimized for robotics and automation components. Our solutions provide space-efficient, traceable and secure storage that integrates with conveyor systems, robotic work cells and automated retrieval systems helping manufacturers reduce waste, improve workflow and protect sensitive parts.

Challenges in Storing Robotics & Automation Components

Storing and handling robotics and automation components presents unique operational and engineering challenges that generic storage solutions cannot address effectively:

- Component complexity and variability: Automation systems involve motors, sensors, control units, cabling, tooling, and precision assemblies each with different size, weight and protection requirements.

- Automation integration requirements: Containers must interface reliably with conveyors, robotic arms, AGVs and automated storage and retrieval systems (AS/RS).

- Space optimization pressures: High-density manufacturing and assembly environments require containers that maximize vertical and horizontal space utilization.

- Durability and protection: Robotics components often demand protection from impact, vibration, corrosion and electrostatic discharge.

- Traceability and process control: Automated environments rely on accurate part identification, controlled orientation and error-proof handling.

These challenges make it clear that custom industrial container solutions not standard totes or crates are essential for robotics and automation operations.

Relevant SPS Product Categories for Automation Applications

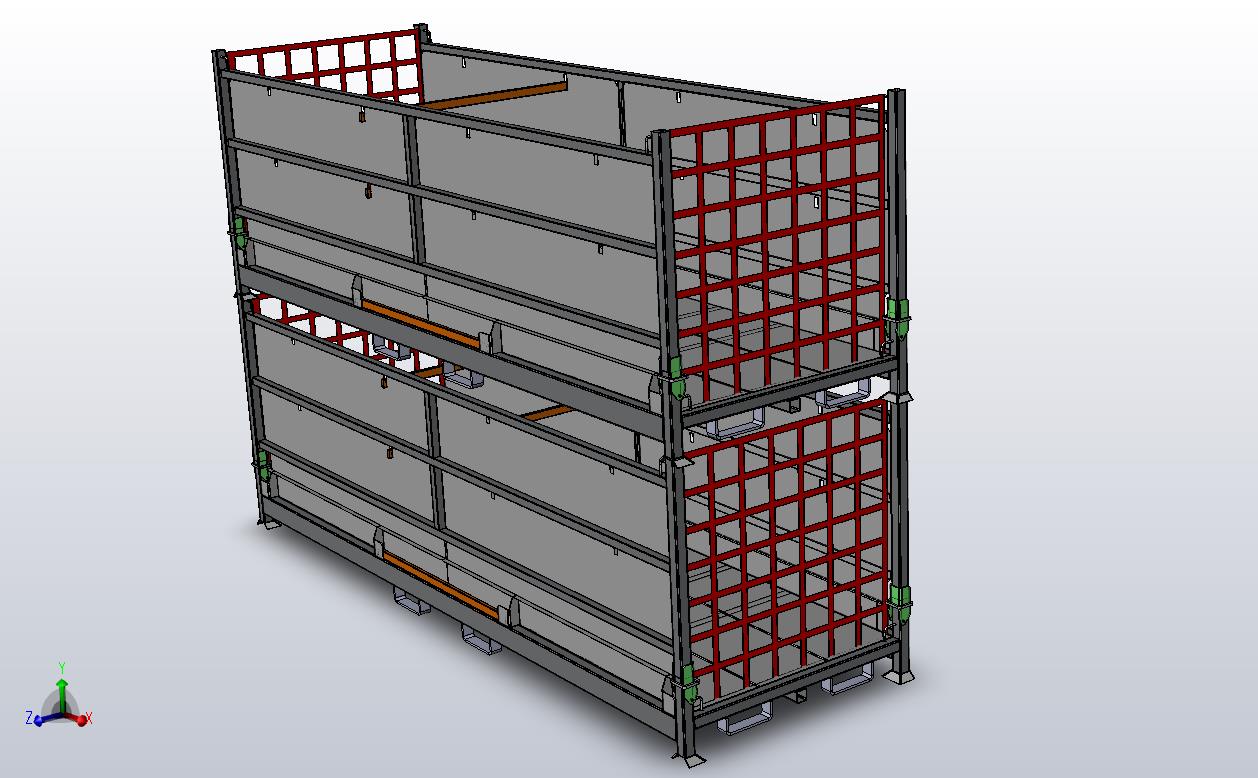

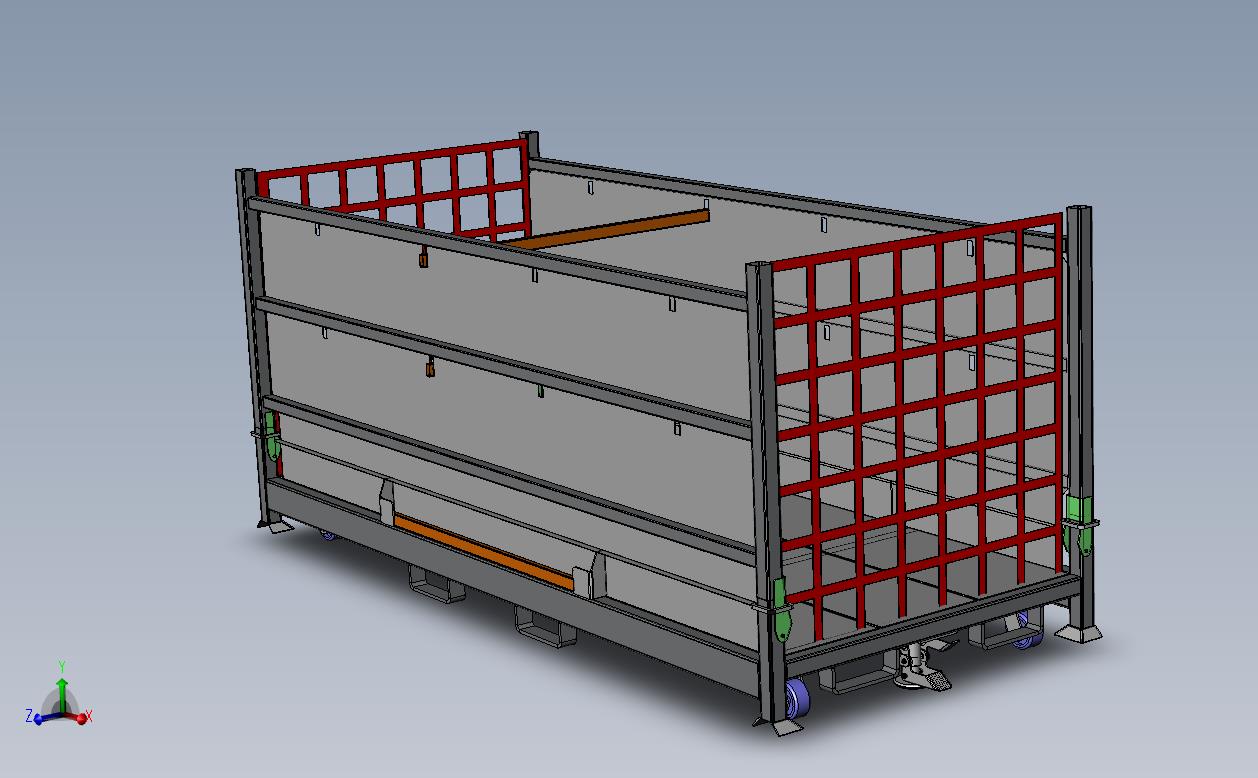

Custom Storage Containers

Custom-designed industrial storage containers developed to support automated handling, consistent footprints, stacking stability, and efficient material flow. These containers are engineered to integrate with conveyors, robotic pick-and-place systems and line-side automation.

Learn more about Custom Storage Container here.

Custom Metal Containers

Fabricated steel and metal containers designed for heavy-duty automation environments. Ideal for high-load components, robotic cells, and industrial applications where strength, longevity, and dimensional precision are critical.

Learn more about SPS Custom Metal Container here.

Industrial Shipping & Storage Racks (Complementary Systems)

Custom racks that work in conjunction with containers to support staging, transport, and storage within automated facilities, ensuring smooth transitions between storage and production.

Learn more about SPS Industrial Shipping and Storage Racks here.

These product categories allow SPS to deliver fully customized container systems aligned with robotics, automation, and Industry 4.0 environments.

SPS Approach to Custom Automation Container Solutions

SPS Ideal Solutions follows an engineering-led, consultative approach to designing custom industrial containers for automation applications.

Application & Workflow Analysis

We begin by understanding how components move through your operation manual handling points, automated interfaces, storage density requirements and environmental conditions.

Custom Engineering & Design

Our team develops container designs using CAD modeling and prototyping to ensure:

- Compatibility with automation equipment

- Optimized dimensions and load distribution

- Durable materials suited to the operating environment

- Custom internal configurations for component stability and protection

Validation for Automated Environments

Each solution is evaluated for performance in real-world automation conditions, including stacking loads, conveyor stability and long-term durability. This approach ensures every container is purpose-built for robotics and automation, not adapted from generic designs.

Solution Delivered

SPS Ideal Solutions delivers end-to-end custom industrial container systems that support robotics and automation operations from storage to point-of-use:

- Improved automation efficiency through containers designed for consistent handling and reliable robotic interaction

- Reduced component damage via engineered protection and stable positioning

- Optimized space utilization with stackable, modular, and automation-ready designs

- Enhanced process control and traceability through standardized container formats

- Scalable solutions that evolve with automation expansion and operational growth

These solutions support a wide range of automation-driven applications, including robotic assembly, automated inspection, and material staging in smart factories.

As robotics and automation continue to transform industrial operations, storage and handling systems must be engineered with the same level of precision as the machines themselves. Standard containers are no longer sufficient for automated environments.

SPS Ideal Solutions provides custom industrial storage containers for robotics and automation components, engineered within proven product categories and tailored to each application’s technical and operational requirements. With a focus on customization, durability, and automation compatibility, SPS helps organizations build efficient, reliable, and future-ready material handling systems.

Looking to develop a custom container solution for your robotics or automation application? Partner with SPS Ideal Solutions to engineer containers that fit your operation not the other way around.

About The Author